As a proud turn-key service provider within the aviation sector, we pride ourselves on creating solutions and top aftercare services for our customers in various locations.

With the rapid growth in our global customer base, TBD is excited to announce a partnership [first of its kind] with Aerotech Solutions Ltd. to provide onsite maintenance services to our customers based at London Heathrow and Gatwick airports.

In partnership with TBD, Aerotech Solutions will be offering non-powered ground support equipment (GSE) maintenance to our customer database, with their team of highly qualified engineers.

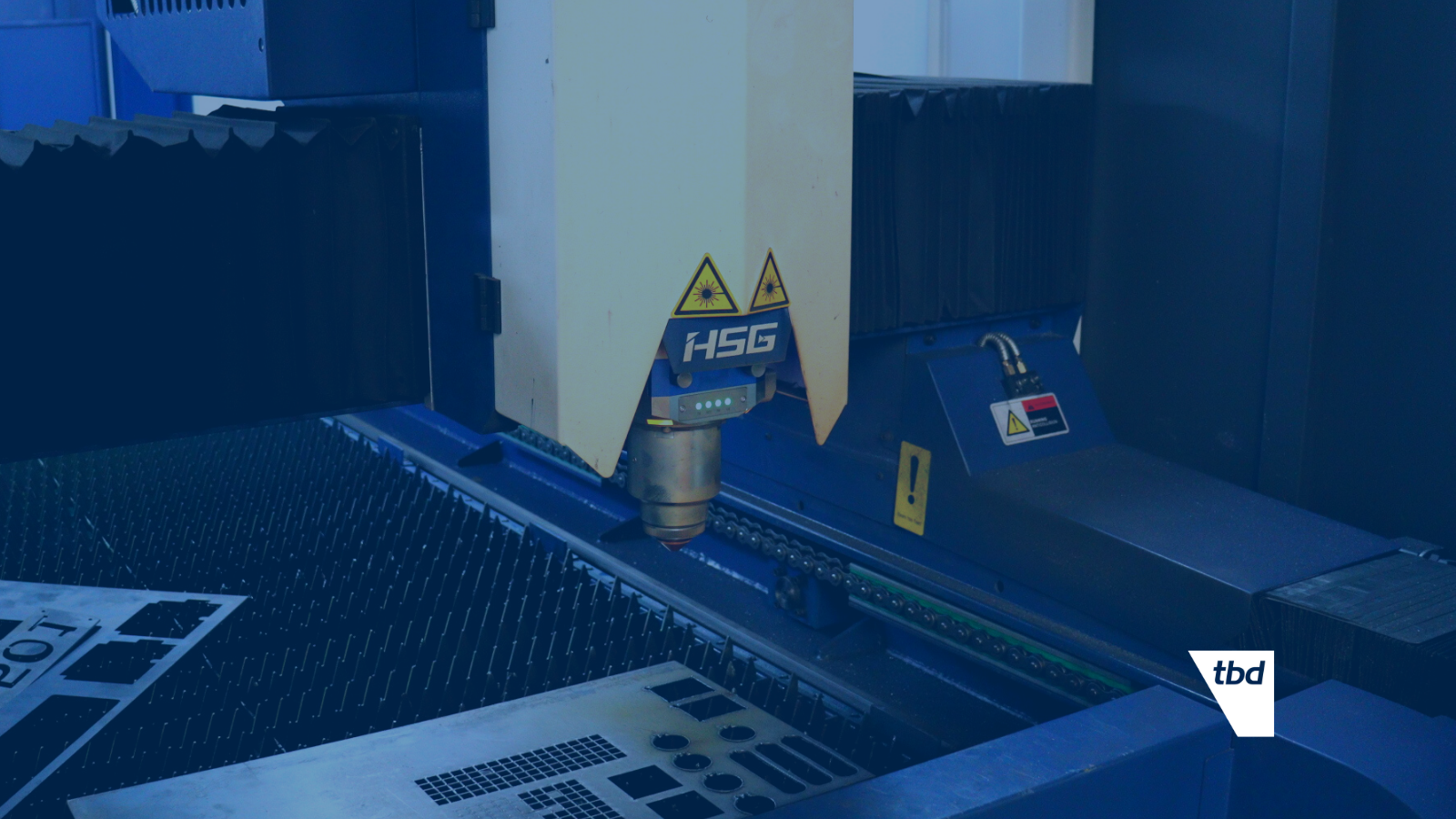

April 2022 saw a step-change in TBD’s efficiency improvements within the business, receiving the latest laser cutting technology from HSG. The G3015X is the latest in high-powered industrial laser cutting and comes at a pivotal time for TBD in its remarkable efforts to engineer new product ranges and create new customer interest.

Efficiency

This modern piece of machinery offers vastly improved efficiency in cutting sheet metal for our entire product range, with a 6kW powered laser in operation, we now have the capability to cut a thicker range of metals which allows TBD to achieve high-quality cutting for more durable and long-lasting equipment.

Accuracy

With an array of technical benefits, the machine promises technology to improve accuracy in cutting all utilised materials including anti-collision protection, state of the art software, intelligent stroke protection and autofocus cutting heads.

Environmental Impact

The machine provides TBD with greatly improved accuracy in parts production and with that comes a range of benefits to our environmental impact.

We anticipate an impacted improvement in the reduction of metal waste and aim to achieve decreasing this by 30% upon review in 2023 approximately 50 tonnes in scrappage.

Secondary processes inherent of the previous plasma operation of grinding and drilling is illuminated with the introduction of the new machinery, allowing TBD to benefit from improved processing time and cost.

With this improved ability to create more parts in-house, we are also anticipating improving our environmental impact by reducing the transport requirements we currently rely upon to operate.

With this new and improved technology, we also foresee lower electricity consumption and noise reduction within our 60,000 sq. ft. workshop facility.

Job Creation

As well as upskilling our existing engineers for full operational capabilities on the machine, we are also opening opportunities to recruit operators for this machinery. All career opportunities can be viewed and applied for on our careers page.